Walcownie Ostrowieckie

WOST S.A.

About us

WOST S.A. is created by a modern managed team of experienced metallurgists, outstanding specialists in our branch. Thanks to this we are open to new concepts, difficult challenges and realize non-standard orders. We create products used in construction, road engineering or power industry.

WOST S.A. – Leading manufacturer of metallurgical products

Walcownie Ostrowieckie WOST S.A. is a leading domestic and European producer of hot-rolled profiles. Our offer of products and services has been developed based on the current market needs. Rolling mill provides customers with a wide range of products of various grades and parameters. This makes us a stable and reliable business partner that plays an important role in supply chains.

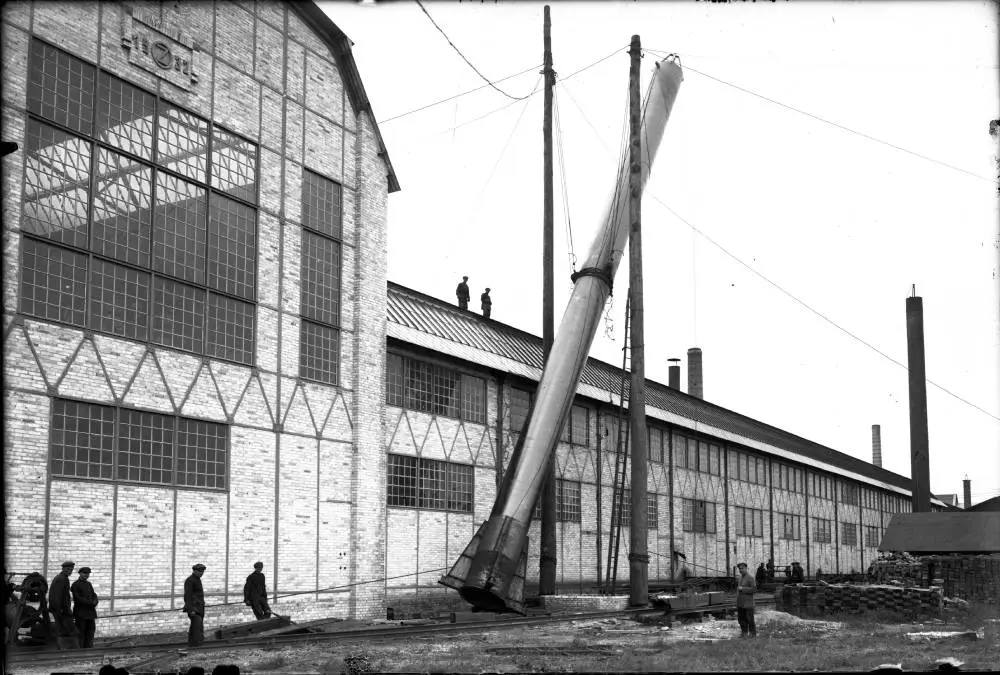

Walcownie Ostrowieckie WOST S.A. they have been operating in the current location since 2015. The rolling mills are located at Centralnego Okręgu Przemysłowego / COP 12a, on the premises of “Old Ironworks” in Ostrowiec Świętokrzyski.

The policy adopted by us is a strategy of responsible business and environmental protection consisting in continuous, integrated and preventive action in relation to processes, products and services aimed at continuous improvement of production efficiency, reducing the risk of health loss and environmental pollution.

In practice, this means the use of technologies that generate less pollution to the environment and optimization of production processes in terms of energy efficiency and their impact on the environment.

For us, as a producer, pro-ecological activities are of particular importance. We have successfully implemented an integrated ISO system, including ISO 14001: 2015 used in responsible environment management, and we are currently implementing the EcoManagement and Audit Scheme (EMAS) model.

Our story

What makes us different

Wide offer

We have a wide range of products that are characterized by the highest quality of workmanship, appreciated all over the world.

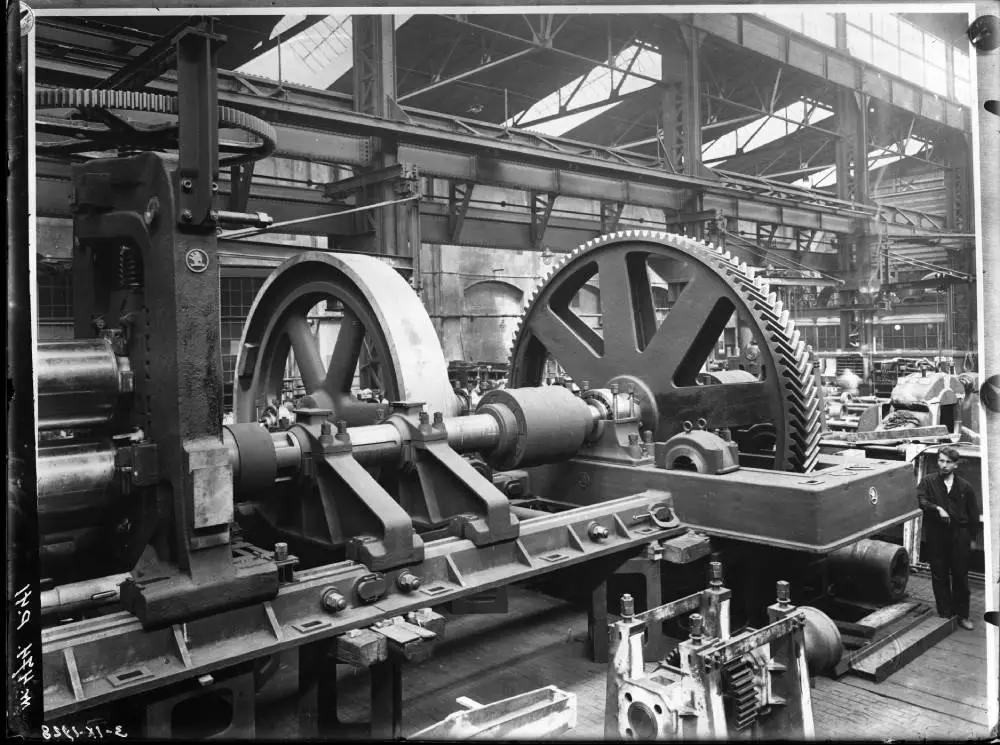

Traditional technology

We produce on traditional lines that are constantly modernized. We carry out the traditional rolling process carry out two-way rolling.

Non-standard realizations

For the purposes of construction or energy, we carry out non-standard orders in accordance with the customer’s requirements.

Ecological approach

For us, pro-ecological activities are of particular importance – we constantly improve the production line, reducing the negative impact on the environment.

Fast delivery time

We provide a fast order fulfillment process. All thanks to an efficient production line and high stock levels.

Frequent production cycles

Frequent changes in production cycles significantly accelerate the execution of orders for our customers.

Our products in the world

Polski

Polski English

English Deutsch

Deutsch Español

Español Русский

Русский Français

Français